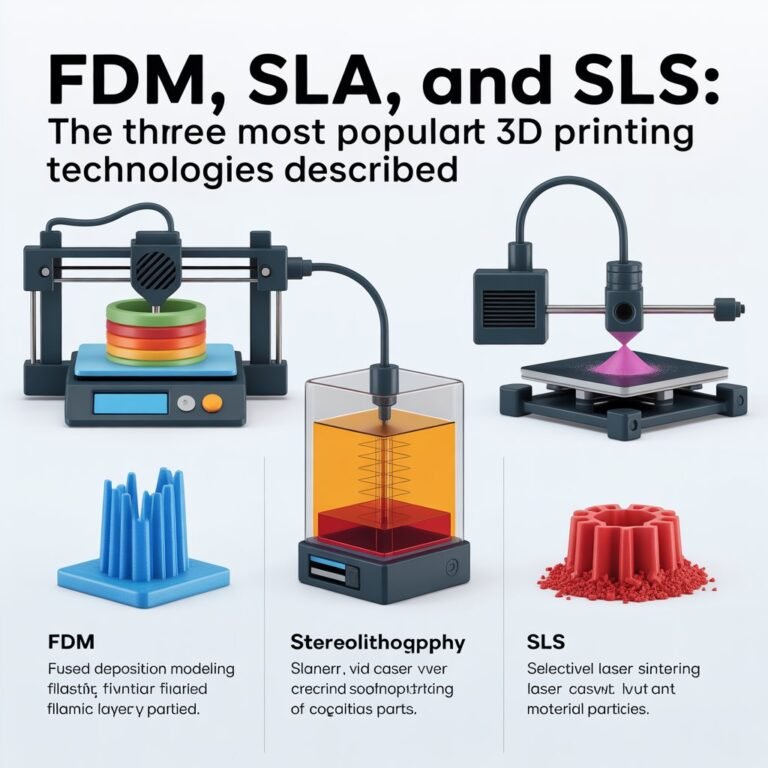

3D printing is one of the radical technologies in the design and production era. It has changed how industries design, validate, prototype, and even create hasty ideas into concept models, to extremely finished products. Among the numerous existing technologies of 3D printing that have been introduced so far, however, three can be distinguished in terms of the diversity, accuracy, and popularity, namely: Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

The first step to selecting the best technology that you can apply in your next project or product would be to understand how they operate, their pros and cons. The case study of the complexities of the design, views of the materials, and production costs can be used to make quality decisions as an engineer, designer, or businessman through the knowledge of the FDM, SLA, and SW.

1. Fused Deposition Modeling (FDM)

How FDM Works

The most widely known and the least expensive technology of 3D printing is FDM. It operates on the principle that when a thermoplastic filament is forced through a nozzle, two hot nozzles are achieved, and the material is deposited by the filament in layers on a built platform. Similarly, a new layer is added to the earlier one when it becomes cool, and the sequence of the layers is completely inverted.

Key Materials

- PLA (Polylactic Acid): It is cheap, can be easily printed, it is biodegradable.

- ABS (Acrylonitrile Butadiene Styrene): Impact-resistant, tough, hard, and heat-resistant.

- PETG, Nylon: They are used as flexible materials or for industrial use.

Benefits

- Cheap and convenient: Can be used in first-level Rapid Prototyping Services and in learning.

- Fast turnaround: Fast concept models and functional components.

- Facility of operation: Facile establishment, maintenance, and material logistics.

Limitations

- Whereas FDM is exceptional in terms of value and speed, it does have observable lines of its layers and may not be as precise and surface finish as other technologies. In addition to that, complex geometries may require support structures, adding post-processing stages.

Best for: Simple prototypes, functional mechanical parts, and low-cost design verification.

2. Stereolithography (SLA)

How SLA Works

The earliest commercialized 3D printing process was the Stereolithography (SLA), which was reputed to have high precision and flat surface finish. The SLA printers are printers that are manufactured to employ a UV laser to cure and solidify resin liquids in layers in a vat sequentially. After printing, the part is washed and cured under UV light so as to realize the end mechanical properties.

Key Materials

- Standard Resin: Applied for visual prototypes and aesthetic models.

- Tough Resin: Replicates ABS-like strength for functional parts.

- Castable and Transparent Resins: Used in jewelry, dental, and optical industries.

Advantages

- High precision and detail: SLA parts possess very fine resolution and very good surface quality.

- Smooth finish: Little post-processing needed for aesthetic applications.

- Versatile materials: Suitable for industries requiring accurate prototypes and functional parts.

Limitations

- Resin material can be more expensive than thermoplastics and is mostly brittle under stress. The post-processing steps (washing, curing, and handling) are time time-consuming than those in FDM.

Ideal for: High-detail prototypes, dental and medical models, and consumer product design.

3. Selective Laser Sintering (SLS)

How SLS Works

SLS is attractive to a good laser in warming up the materials used in it to highly elevated temperatures. These are principally nylon substances, and in the solid state. SLS will not occur until the surrounding unused powder has formed the form of natural support, unlike SLA and FDM. And that too during printing. This quality allows the SLS to be used with a great deal of flexibility in interlocked or hollow, fastidiously complicated shapes.

Key Materials

- Nylon (PA11, PA12): This is a tough, lightweight, and high-strength nylon.

- TPU: It offers flexibility and elasticity for designing functions.

- Composite Powders: They are carbon/ glass mixtures to become more rigid.

Advantages

- Stable and working parts: SLS produces mechanically valuable parts that fit the use conditions.

- Yet no assists required: Supports fewer design constraints.

- Best in the small-batch: The first choice in industrial and engineering.

Limitations

- The SLS technology is more costly to operate and maintain, and the finish that it produces is a bit coarser in comparison with SLA. A further de-powdering and smoothing is made, followed by post-processing.

Ideal for: Engineering-grade prototypes, functional parts, and low-volume production runs.

FDM, SLA, and SLS: A Comparison

| Feature | FDM | SLA | SLS |

| Accuracy | Moderate | High | High |

| Surface Finish | Moderate | Excellent | Good |

| Strength | Moderate | Medium | High |

| Material Variety | Wide | Resin-based | Powder-based |

| Cost | Low | Medium | High |

| Supports Required | Yes | Yes | No |

These two technologies have their merits. FDM is appropriate when there is a need to have a low cost, SLA when there is an attempt to have better accuracy, and SLS when there is an attempt to have functional purposes. The most appropriate will be designed depending on the design requirements, material requirements, and manufacturing objectives.

The Use of Professional 3D Printing Services

Despite the fact that the additive manufacturing process has been democratized by desktop 3D printing, the quality of the results is sometimes out of reach in the home. This is where [AIXI 3D Printing Manufacturing services] fits, considering the many years of experience in Rapid Prototyping Services, which AIXI offers the latest solutions to all the major technologies of 3D printing, FDM, SLA, and SLS to offer accuracy, performance, and reliability.

They provide their services at every stage of the product development, including concept modeling and prototype, until complete production. Need a single component that needs to be customized, or a whole manufacturing solution? AIXI 3D Printing Manufacturing services are precise, fast, and quality, and could be confirmed as such by international standards.

Conclusion

The 3D printing time is constantly developing, and offers more prospects in every area, such as auto and aerospace, medical, and consumer products. FDM, SLA, and SLS are still the three most reliable and multifunctional technologies that make this revolution. FDM must be used when the prototypes are cost-effective and when the print design is to be revised. The most important thing to you is SLA, and you must select it with the utmost care and aesthetic taste. SLS is required when durability and functionality are put first.